Over 65 years of experience at your service

Plastical is a company specializing in the design, construction, and molding of plastic materials and technopolymers on behalf of third parties.

Founded in the distant year of 1965, Plastical was among the first Italian companies to operate in the field of plastic molding. Customer focus, the quality of molded products, and fast and efficient service are the fundamental elements of the company's DNA.

Today, our press park also boasts machines equipped with a rotating table and an additional cylinder for the molding of BI-MATERIAL articles.

Mission

Plastical aims to be a reliable reference point for those seeking a trustworthy partner for the production of technical components in plastic materials.

The company's mission is pursued through continuous updating and study of new materials, flexibility in molding techniques, and supporting the customer in the phases of industrialization and product design.

The expertise gained over more than 65 years of activity and the young, dynamic, and skilled personnel allow us to offer advanced customized solutions to clients in various industrial sectors

-

1965

Foundation

-

1966

The beginning of collaboration with the American company Sunbean (Chrysler Group) and the purchase of a 550-ton initiation machine (the largest in Emilia Romagna at the time)

-

1968

Opening of the high vacuum metallization technology department

-

1980-1990

Plastical becomes a supplier to the Ferrero Group and the Guaber Group (currently Coswell)

-

1990-2000

Plastical enters the fashion market in the bags sector with brands such as Mandarina Duck, Prada, Piquadro, and Redwall

-

2007

Entry into the active protection market through the acquisition of Attiplast Srl

-

2010

Complete restructuring of the Cadriano headquarters, including the construction of a building in B class (PV System 100 kWp, Heat Pumps, Radiant Floor, External Insulating Coat)

-

2010-2015

Commencement of the internationalization process with services provided in 10 countries

-

2015

Generational transition through the signing of family agreements

-

2015-2020

Consolidation of the internationalization process with services provided in over 20 countries

-

2017

Definitions of the SYSTEM POLE project within the framework of the European Union's HORIZON 2020 framework program

-

2020

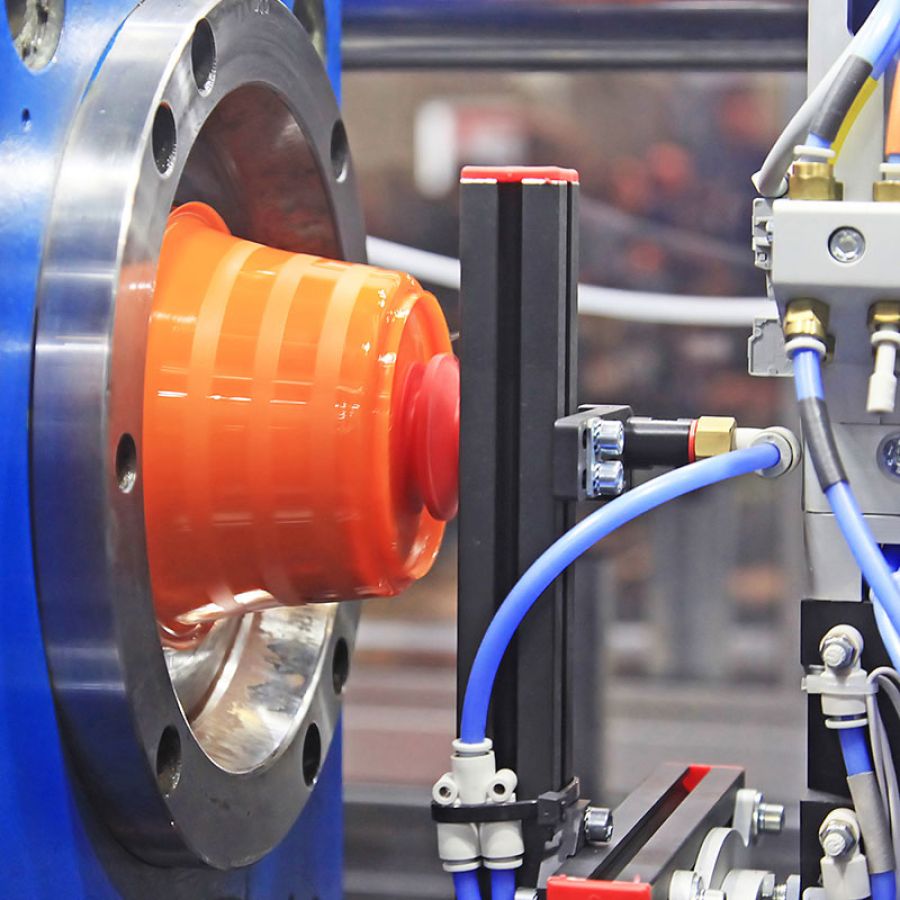

Completion of the first BI-MATERIAL product, namely the TOP V6 PLAQUETTE

-

2021

Obtaining a European Patent for the BI-MATERIAL Technology in the field of active agricultural protections

Quality

Certified

Our Quality Management System is certified according to international standards:

UNI EN ISO 9001:2015

for the following products/services:

- Design and injection molding of technical articles for agricultural cultivations and third parties.

- Design and construction of molds.

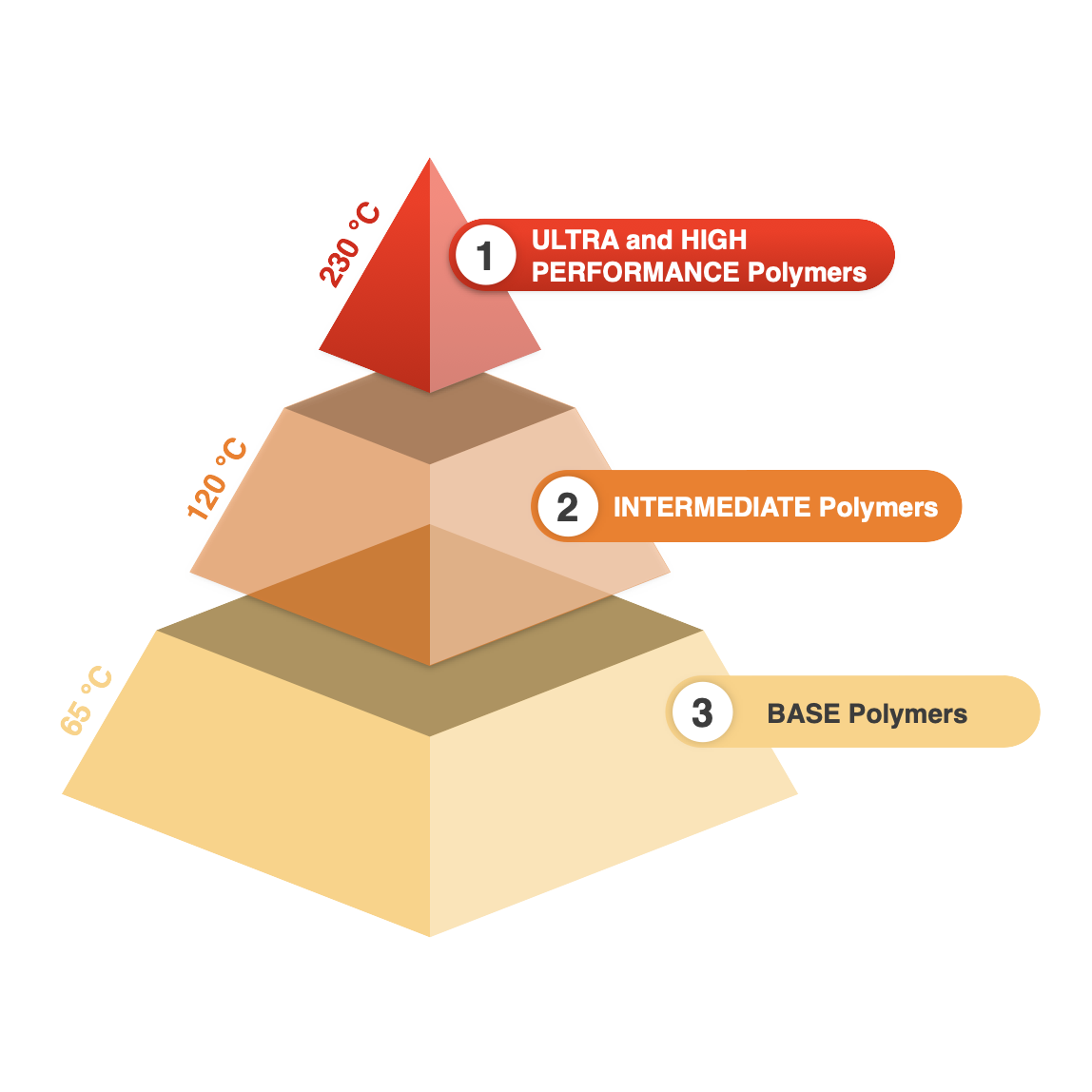

Materials

We create numerous solutions thanks to our decades of experience in combining polymers and elastomers for articles with different functional, strength, and aesthetic characteristics.

1. ULTRA and HIGH PERFORMANCE polymers

PAEK, PEK, PEEK, PEKK, PEKEKK (Polyaryletherketone)

PAI (Polyamide-imide)

PAA, PPA, PAMXD6, PARA (High-Performance Polyamides)

PEI (Polyetherimide)

PES, PPSU, PSU (Polysulfone)

PPS (Polyphenylene Sulfide)

LCP (Liquid Crystal Polymer)

PVDF (Polyvinylidene Fluoride)

2. INTERMEDIATE Polymers

PC (Polycarbonate)

PA6, PA11, PA12, PA46, PA66, PA69, PA610, PA612, PA-3-T, PA6I, PA6T, PA-PDA (Polyamide)

TPU, PUR (Thermoplastic Polyurethane Elastomer)

POM-C, POM-H (Polyoxymethylene)

PBT (Polybutylene Terephthalate)

PET (Polyethylene Terephthalate)

COC (Cyclic Olefin Copolymers)

3. BASE Polymers

ABS (Acrylonitrile Butadiene Styrene)

PS (Polystyrene)

HDPE, LDPE (High-Density Polyethylene, Low-Density Polyethylene)

PP (Polypropylene)

Discover our services

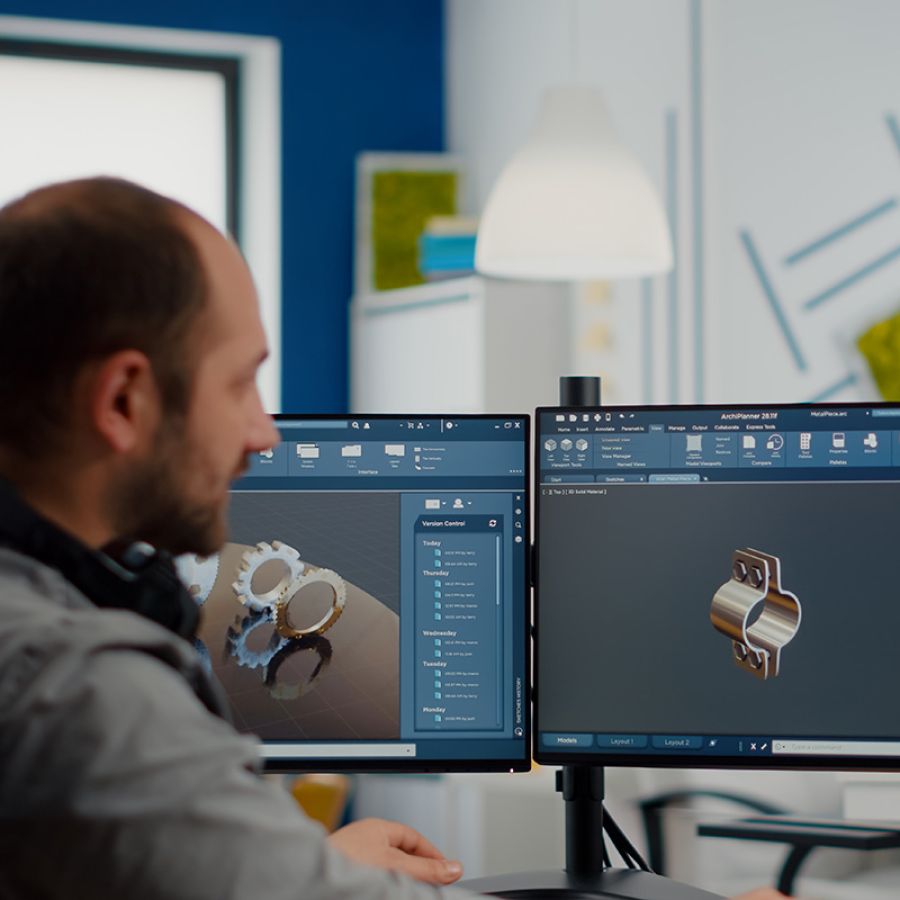

DESIGN and ENGINEERING

3D Modeling

Reverse Engineering

FEM Analysis

Prototyping

Metal Replacement

THIRD-PARTY MOLDING

Production Department

Metal Co-Molding

Bi-material Molding

MES (Manufacturing Execution System)

Reconditioning and Assemblies

Quality Control and Testing

BIMATERIAL TECHNOLOGY

Printing two different thermoplastic materials in the same mold.

METAL REPLACEMENT

Converting components previously manufactured in metal to plastic materials.